Non-Catalytic Heated Filament Gas Indicators (Tankscopes)

Operating Principle

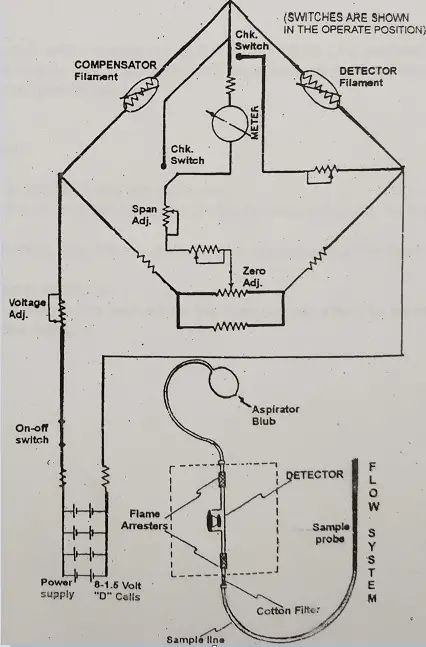

The sensing element of this instrument is usually a non-catalytic hot filament. The composition of the surrounding gas determines the rate of loss of heat from the filament, and hence its temperature and resistance.

The sensor filament forms one arm of a Wheatstone Bridge The Initial zeroing operation balances the bridge and establishes the correct voltage across the filament, thus ensuring the correct operating temperature During zeroing, the sensor filament is purged with air or inert gas that is free from hydrocarbons. As in the Explosimeter, there is a second identical filament in another arm of the bridge which is kept permanently in contact with air and which acts as a compensator filament.

The presence of hydrocarbon changes the resistance of the sensor filament and this is shown by a deflection on the bridge meter. The rate of heat loss from the filament is a non-linear function of the hydrocarbon concentration and the meter scale reflects this non-linearity. The meter gives a direct reading of % volume hydrocarbons. When using the instrument, the manufacturer’s detailed instructions should always be followed. After the instrument has been initially set at zero with fresh air in contact with the sensor filament, a sample is drawn into the meter by means of a rubber aspirator bulb. The bulb should be operated until the meter pointer comes to rest on the scale (usually within 15-20 squeezes) then aspirating should be slopped and the final reading was taken. It is Important that the reading should be taken with no flow through the instrument and with the gas at a normal atmospheric pressure.

The non-calatytlc filament is not affected by gas concentrations In excess of its working scale. The instrument reading goes off the scale and remains in this position as long as the filament is exposed to the rich gas mixture.

Instrument Check Procedures

The chocking of a non-catalylic heated filament instrument requires the provision of gas mixtures of a known total hydrocarbon concentration.

The carrier gas may be air, nitrogen or carbon dioxide or a mixture of these Since this type of instrument may be required to measure accurately either low concentrations (1%-3% by volume) or high concentrations (greater than 10% by volume) It is desirable to have either two test mixtures, say 2% and 15% by volume, or one mixture between these two numbers, say 8% by volume. Test gas mixtures may be obtained in small aerosol type dispensers or small pressurised gas cylinders, or may be prepared in a special test kit.

The measuring circuit is a balanced Wheatstone’s bridge.

Three major steps must be taken before the samples are drawn into the instrument for analysis:-

- The detector chamber must be swept free of C/H gases and filled with inert gas or air.

- Batteries must be turned “on”, and the proper voltage applied to the bridge.

- The bridge must be. balanced to zero deflection on the meter with IG or fresh air in the filament chamber.

The MSA tank scope is sensitive to tilt, so it is important to keep the instrument in a normal, upright position during operations or there may be a significant error in instrument readings.

can you tell me more in detail about compensator filament